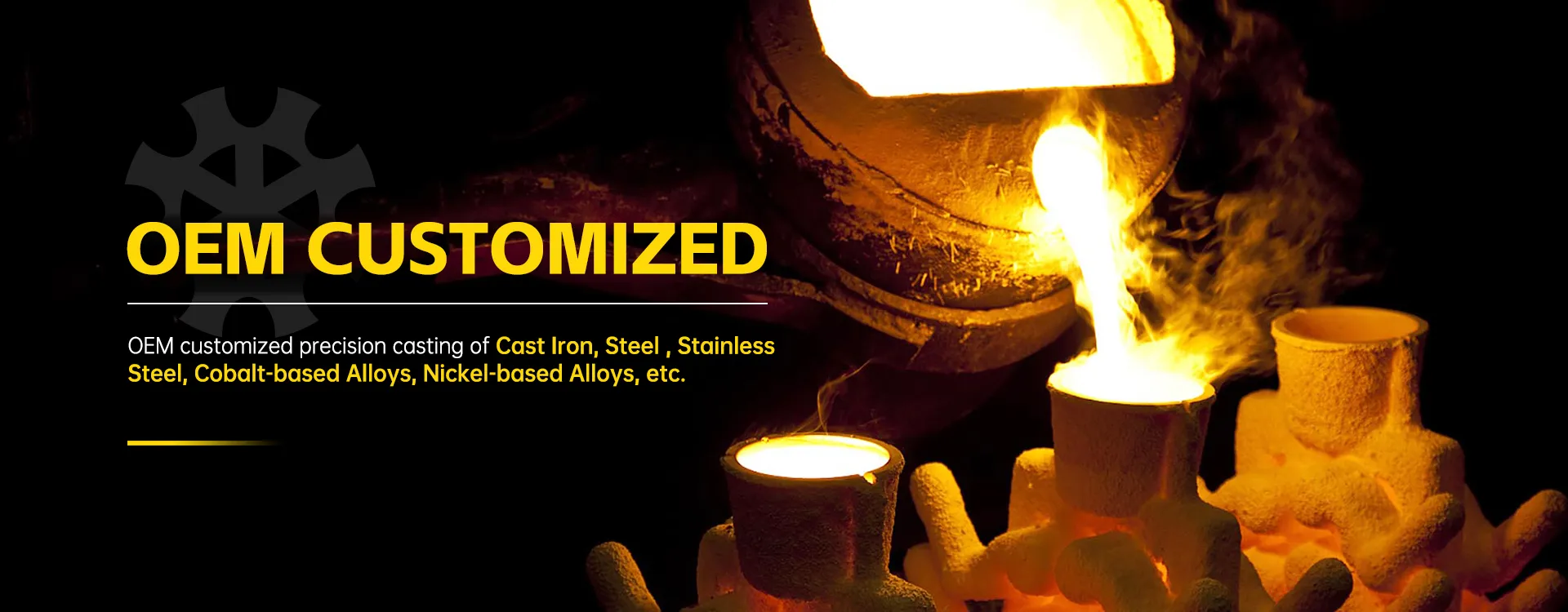

Investment casting(lost-wax casting) is a process that uses a precise, disposable model made of a fusible wax material. This model is then coated with multiple layers of refractory material to create a complete mold shell. The wax model is then melted away by heating, resulting in a hollow ceramic mold shell that perfectly replicates the shape of the original wax model. Molten metal is then poured into the mold shell, ultimately producing a metal casting identical to the original wax model. This process is an indispensable core technology in high-end manufacturing, particularly suitable for the production of critical components with complex shapes, expensive materials, and demanding performance requirements. Using this process, we can produce precision parts made of various materials, including steel, stainless steel, and special alloys (such as aluminum alloys, nickel-based alloys, and special stainless steels,etc.).